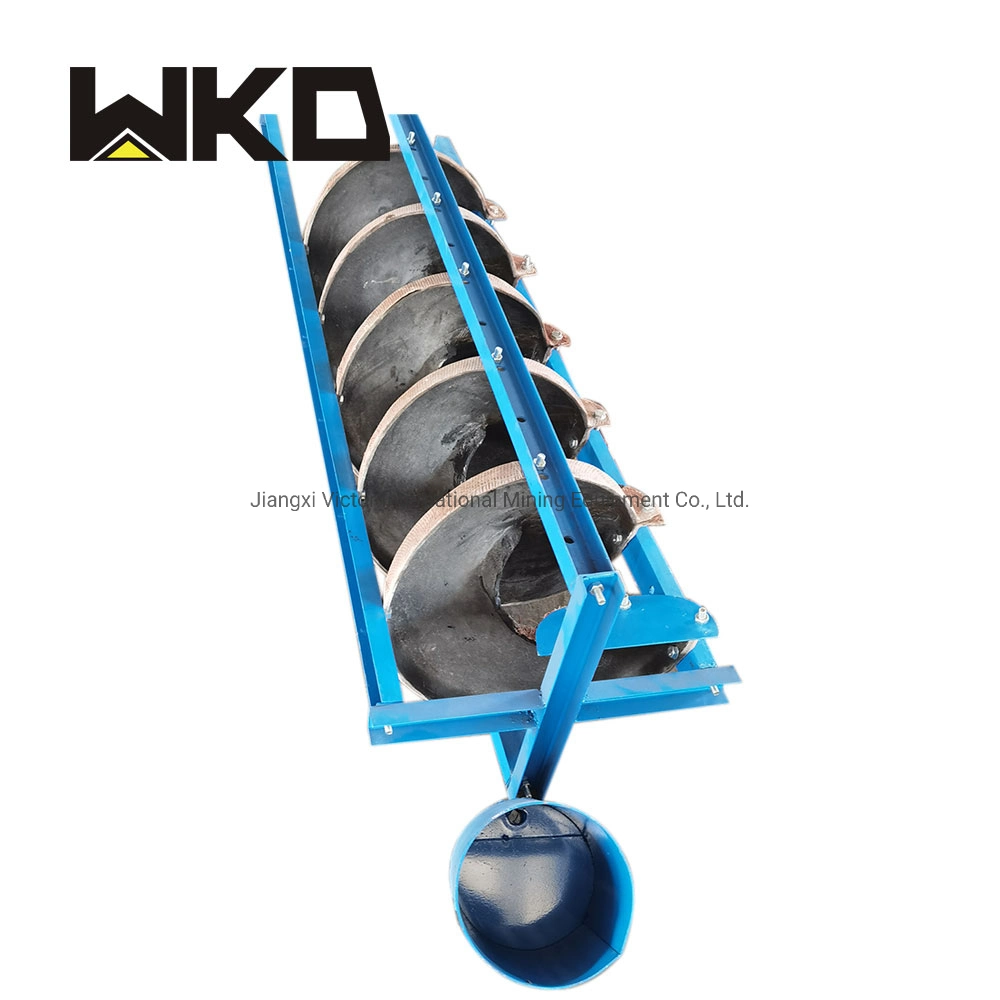

Lab Scale Vertical 5ll-600 Zircon/Gold/Copper/Coal/Chrome Mineral Processing Spiral Concentrator for Sale

Basic Info

| Model NO. | 5LL-600 |

| Warranty | 1 Year |

| Color | Multi Color |

| Customized | Customized |

| Condition | New |

| After-sales Service | 1 Year |

| Product Name | Spiral Concentrator |

| Feeding Size | 0.2-0.2mm |

| Capacity | 0.4-0.8t/H |

| Application | Mining |

| Installation | Technical Guidance |

| OEM | Yes |

| Shipping Way | by Sea, DHL, FedEx, UPS, TNT, EMS |

| Pay Terms | Tt, Paypal, Credit Card, Western Union |

| Transport Package | No Package |

| Specification | 700*700*2150mm |

| Trademark | WKD |

| Origin | China |

| HS Code | 8474100000 |

| Production Capacity | 0.4-0.8t/H |

Product Description

Introduction

Spiral chute, a new gravity separation machine, applicable to processing iron, tin, tungsten, tantalum, niobium, gold, coal and other metal separation from particle size 0.6mm to 0.05mm.It has been used in to enrichment the particle size 0.3-0.02 millimeters fine grain like iron, tin, chromite,ilmenite,tungsten,zinc, tantalum-niobium, gold, coal, monazite, rutile, zircon and other low-grade ores. The non-metallic minerals which have a big enough specific gravity difference.

Features

1. Reasonable structure and small occupation area2. High recovery, high efficiency, and precise separation3. Non-required power4. Light in weight, anti corrosion, rust and wear resistant5. Simple installation and Minimal maintenance requirements6. Low operating cost and long working life7. Reliable running with minimal operator attention8. Strong adaptability to fluctuation of feeding amount, density, size and grade9. The surface of corundum forms strong friction the concentration effect surpass plastic surface.

Working PrincipleAs larger and heavier particles sink to the bottom of the sluice faster and experience more drag from the bottom, they travel slower, and so move towards the center of the Spiral Chutes. Conversely, light particles stay towards the outside of the spiral, with the water, and quickly reach the bottom. At the bottom, a "cut" is made with a set of adjustable bars, channels, or slots, separating the low and high density parts

Structure

Our spiral chute is a gravity separation equipment of separation different weight mineral by inertial centrifugal force pulp produced in helix turning motion.

1. Separation Hopper 2. Feeder Trough 3. Spiral Section4. Stand 5. Ore Receiving Hopper 6. Annular Collecting Hopper

Technical Parameters

Model | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 |

Outside dia(mm) | 1500 | 1200 | 900 | 600 | 400 |

Pitch(mm) | 540/720 | 900/720/540 | 675/540/405 | 450/360/270 | 240/180 |

Pitch Dia Ratio | 0.75/0.6/0.45 | 0.75/0.6/0.45 | 0.75/0.6/0.45 | 0.75/0.6/0.45 | 0.6/0.45 |

Lateral slope | 9 | 9 | 9 | 9 | 9 |

Maximum starts per column | 4-2 | 4-2 | 4-2 | 3 | 2 |

Feeding Size(mm) | 0.3-0.02 | 0.3-0.03 | 0.3-0.03 | 0.2-0.02 | 0.2-0.02 |

Feeding Density(%) | 25-55 | 25-55 | 25-55 | 25-55 | 25-55 |

Capacity(T/H) | 8-6 | 4-6 | 2-3 | 0.8-1.2 | 0.15-0.2 |

| Length (mm) | 1560 | 1360 | 1060 | 700 | 460 |

| Width (mm) | 1560 | 1360 | 1060 | 700 | 460 |

| Height (mm) | 5230 | 5230 | 400 | 2600 | 1500 |

Weight (Kg) | 800 | 600 | 400 | 150 | 50 |

Packing

1.1 set with nude package in a container2.1 set with steel frame when with LCL loading

Detailed Images

Company Information

Victor is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters and 20,000 square meters for workshop, with various large modernized machinery facilities, professional R&D team and installation team. With 32% market share in China and the rest to overseas, already successfully exported to over 50 countries, such as USA, England, Australia, Brazil, Turkey, Italy, Russia, South Africa, Zimbabwe, Sudan, Ghana, Congo, Morocco, India,Indonesia, Malaysia, Philippines, North Korea, Mongolia, Vietnam, Thailand etc.Our goal is to provide one-stop service for you and assist you to solve all problems from investment to his return in the field of mining, including the preliminary mineral analysis, mineral processing test, engineering design, equipment debugging and technical training etc.. We are expert especially at mining separating and lab mining plant, main products as below:Gold trommel wash plantShaking tableSpiral chute separatorCentrifugal gold concentratorJig separator machinesWaste recycling machineGrinding and mill crusherFlotation cell machineMagnetic separatorLaboratory mining plantPackage: FCL & LCL export standard container 20GP/40GP/40HQ. FCL: main machinery gold shaking table in nude package and bulk in container, spare parts in wooden box or as your special requirementLCL: machinery are packed in steel frame, base and deck are separately packed. Shipping: by sea shipment, by air shipment or by courier express, it depends on you.Payment Terms: T/T or L/C is preferable. T/T: 30% deposit and the balance before delivery We will take photos for your products when finished and show you before delivery. Also keep you informed for any updated information including shipping before you receive it, to let you rest assured.Delivery time: shipped in 15 days after paymentFAQ1.How is the quality of your products? (mining equipment/machine)Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.2.Guaranteed?Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as wedescribed or the promise before you place order, we promise 100% refund.3.How about price?Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.4.Service and Payment Terms?Answer: We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice;Finished product pictures will provide to customers before delivery.Our Service1) Pre-sale service: Freely provide project designing, process designing, choosing suitable equipment for you.2) Medium-sales service: Accompany you to complete the acceptance of the equipment, draft the construction scheme and detailed process, and complete process of export3) After-sales service: Offer considerate technical guidance in installation, debugging and operators training. We are available at any time if you need.